Blog

Tombstone Engraving CNC Machine: Precision Tools for Memorials

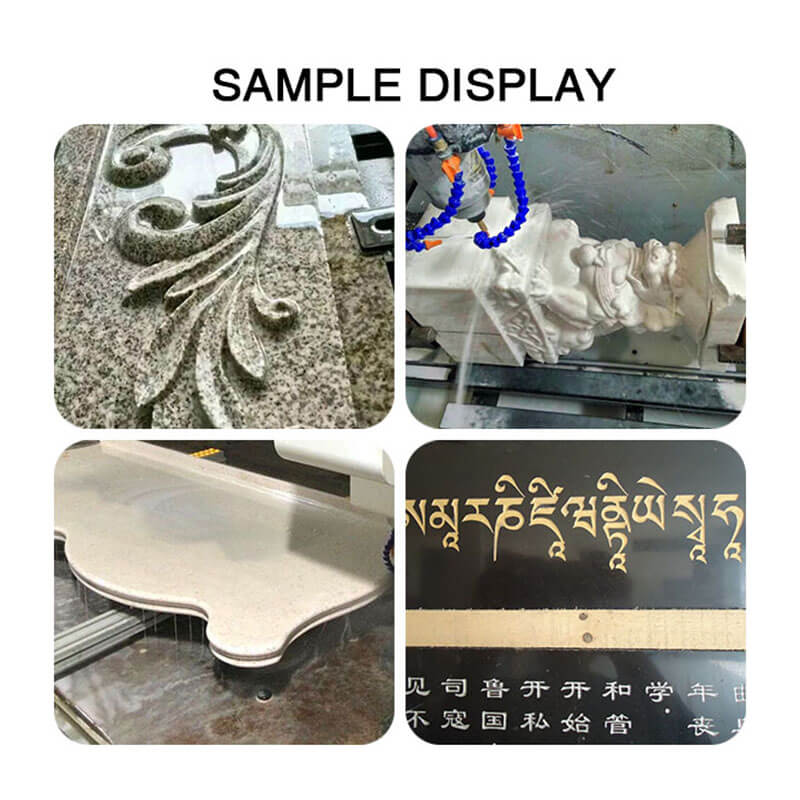

In the world of stone engraving, CNC (Computer Numerical Control) technology has revolutionized how we create memorials and tombstones. The CNC tombstone engraving machine stands out as a specialized tool designed for high precision and intricate detailing, ensuring that every engraving captures the essence of the memories they commemorate. This blog explores the features, benefits, and applications of CNC tombstone engraving machines, highlighting their significance in creating lasting memorials.

A tombstone engraving CNC machine specializes in carving or engraving designs, text, and images onto tombstones or grave markers. Equipped with advanced CNC technology, these machines achieve high precision and intricate detailing in the engraving process.

What is a CNC Tombstone Engraving Machine?

A CNC tombstone engraving machine is an advanced piece of equipment specifically designed to carve or engrave designs, text, and images onto tombstones and grave markers. Utilizing sophisticated CNC technology, these machines deliver exceptional accuracy, allowing users to create custom designs that honor loved ones.

CNC Machine for Tombstones Key Features

- Precision Control

CNC machines offer precise control over the engraving process, ensuring that designs are reproduced with exacting standards. This precision is crucial for creating intricate patterns and lettering that stand the test of time. - Customization Options

One of the standout features of CNC machines is their ability to accommodate custom designs, fonts, and layouts. This flexibility allows users to tailor memorials to individual preferences, ensuring that each piece is unique. - Multi-Axis Capability

Many CNC engraving machines are equipped with multi-axis capabilities, enabling them to engrave on both flat and curved surfaces. This is essential for tombstones, which often feature varied shapes and contours. - Durable Tools

CNC tombstone machines typically use diamond-tipped bits or specialized engraving tools designed to handle hard materials such as granite and marble. These durable tools ensure clean cuts and long-lasting engravings. - User-Friendly Software

Most CNC machines come with intuitive software that simplifies the design process. Users can easily import graphics, adjust designs, and visualize the final product before engraving, streamlining the workflow.

Tombstone CNC Machining High-Speed Performance and Stability

Our CNC stone machine features a lathe bed welded with thick channel steels and square tubes, processed through high-temperature tempering treatment and vibrating stress relief (VSR). This construction reduces residual stress, providing excellent stability and preventing deformation during operation. The combination of a high-speed water-cooling spindle and high-performance subdivision driver allows for extended periods of work without overheating, ensuring that you can complete projects efficiently.

Enhanced Efficiency with Water Cooling

The machine features a water tank and a double water cooling system, which significantly enhances operational efficiency.This setup keeps the spindle cool during long engraving sessions, which not only protects the equipment but also improves the quality of the engraving by preventing material warping.

Dust Protection for Longevity

With a practical three-axis dust-proof system, our CNC machine is designed to protect critical components like guides and bearings. This feature ensures a longer lifespan for the machine and enhances its efficiency by reducing maintenance needs.

Benefits of Using CNC Tombstone Engraving Machines

- High Quality

The precision of CNC engraving results in high-quality finishes that can endure harsh weather conditions over time. This durability ensures that memorials retain their beauty and integrity for years to come. - Efficiency

CNC machines can engrave complex designs significantly faster than manual methods. This efficiency translates to quicker turnaround times, allowing memorial providers to meet the demands of their clients more effectively. - Consistency

Each engraving produced by a CNC machine is uniform, ensuring that multiple tombstones can be produced with the same design and quality. This consistency is particularly important for memorial parks and family plots.

Applications of CNC Tombstone Engraving Machines

1. Grave Markers

CNC machines excel in creating custom engravings for individual names, dates, and personal messages on grave markers. This personalization allows families to honor their loved ones uniquely.

2. Memorials

For larger structures, such as memorials, CNC machines can handle intricate designs and depictions. These machines can create detailed engravings that celebrate a person’s life and legacy.

3. Bronze Plaques

CNC engraving technology is not limited to stone; it can also be applied to materials like bronze. Engraving on bronze plaques allows for additional commemorative options in memorial settings.

4.Tombstone Engraving CNC Machine Artistic Applications

Beyond traditional memorials, CNC engraving machines can be used for artistic purposes, such as creating sculptures and decorative pieces. Their versatility makes them valuable in various industries.

How Does a Tombstone Engraving CNC Machine Work?

A stone CNC machine operates through a computer-controlled cutting mechanism that utilizes diamond-tipped bits for precise engraving. To begin the process, an operator creates a digital model of the object to be carved. This model is then sent to the CNC machine, which follows a predefined path, carving the stone as specified.

These machines achieve remarkably precise cuts, down to fractions of an inch, using high-quality materials that can handle the rigors of stone engraving. Once the machine receives the digital instructions, it is powered by compressed air, moving the cutter rapidly across the stone surface, ensuring both efficiency and accuracy.

Buying a CNC Tombstone Engraving Machine

Inquiry and Customization

If you’re considering purchasing a CNC tombstone engraving machine, the process begins with an inquiry. Share details about the materials you plan to use, your maximum working size, and the types of products you wish to create. Your budget is also an important factor in determining the best machine for your needs.

Quotation and Production

Once you’ve provided your requirements, a detailed quotation will be prepared, including machine specifications, photographs, and pricing. After confirming the order and paying a deposit, production begins, encompassing everything from 3D design to final inspection.

Testing and After-Sale Service

After manufacturing, you’ll receive a video showcasing the machine in operation. Once you approve the final product, we will ship the CNC router.. Post-sale, comprehensive support, including installation videos and a dedicated service team, ensures you can make the most of your new equipment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.