Blog

Foam Cutter CNC for Fast, Accurate Foam Cutting Solutions

In a wide range of industries, from packaging and furniture manufacturing to automotive and design, foam is a versatile and essential material. Whether it’s used for cushioning, insulation, or creating custom designs, cutting foam with precision is crucial to ensure the final product meets exact specifications. Traditional cutting methods can be time-consuming and labor-intensive, leading to inefficiencies and inconsistent results. Enter Foam Cutter CNC (Computer Numerical Control) machines – an advanced solution that brings speed, precision, and versatility to foam cutting. These machines automate the cutting process, ensuring that each piece is cut to perfection every time.

This blog will guide you through everything you need to know about Foam Cutter CNC machines, exploring their features, benefits, and real-world applications in various industries. We’ll also look at how they can transform your business by improving productivity and reducing costs.

Revolutionizing Foam Cutting with CNC Technology

Foam Cutter CNC machines use advanced computer-controlled technology to automate the cutting process of various foam materials, including polystyrene, polyurethane, polyethylene, and memory foam. The precision offered by these machines ensures that foam is cut exactly according to design specifications, whether you’re creating simple shapes or complex 3D forms.

Unlike traditional cutting methods, which often involve manual labor or less accurate equipment, CNC machines offer consistent quality and speed. The system operates based on CAD (Computer-Aided Design) files, which are translated into cutting paths that the machine follows automatically. This means that even the most intricate designs can be reproduced with ease, every time.

Why Choose a Foam Cutter CNC Router?

When it comes to foam cutting, there are several reasons why a CNC machine is the preferred solution. Here’s why more and more businesses are investing in this technology:

- Precision and Accuracy

One of the primary advantages of Foam Cutter CNC machines is their ability to cut foam with high precision. Whether you’re cutting basic blocks or intricate shapes, CNC technology ensures that your cuts are exact, minimizing waste and reducing the need for manual corrections. - Increased Speed

Traditional foam cutting methods can be slow and labor-intensive, especially for large batches. Foam Cutter CNC machines operate quickly, completing tasks in a fraction of the time. This increased speed leads to faster production cycles and a higher throughput, allowing businesses to meet tight deadlines and increase output. - Customization Capabilities

Foam Cutter CNC machines are incredibly versatile. With the ability to handle a wide range of foam materials, thicknesses, and densities, these machines can create customized shapes to meet the unique needs of different industries. Whether you’re cutting foam for packaging, prototyping, or artistic designs, the flexibility of CNC cutting allows for endless possibilities. - Reduced Material Waste

The precision of Foam Cutter CNC machines means that material waste is minimized. CNC software optimizes cutting patterns, ensuring that the foam is used efficiently. This not only saves costs on materials but also contributes to a more sustainable production process. - Low Labor Costs

Automating the cutting process reduces the need for manual labor, which can be expensive and prone to human error. Once the CNC machine is programmed, it can run continuously, reducing the need for constant operator intervention and saving on labor costs in the long run.

Key Applications for Foam Cutter CNC Machines

The versatility of Foam Cutter CNC machines makes them suitable for a wide range of applications. Here are some of the most common industries where these machines are used:

- Packaging Industry

One of the biggest users of Foam Cutter CNC machines is the packaging industry. Foam is commonly used to protect fragile items during shipping, and CNC technology ensures that custom foam inserts are cut with exact precision to fit the shape of products. This not only protects the goods but also reduces the risk of damage during transit. - Furniture Manufacturing

In the furniture industry, Foam Cutter CNC machines are used to cut foam for cushions, mattresses, and upholstery. The precision of the CNC machine ensures that foam components are cut to exact sizes and shapes, improving product quality and ensuring a perfect fit. - Automotive Industry

The automotive industry relies on foam for various applications, including seat padding, insulation, and soundproofing. Foam Cutter CNC machines enable automotive manufacturers to produce consistent, high-quality foam components for their vehicles, improving comfort and performance. - Model Making and Prototyping

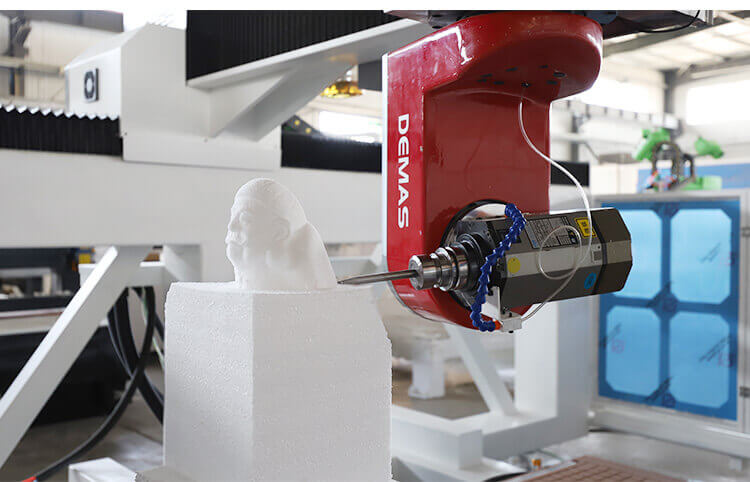

Foam is commonly used in model making and prototyping due to its lightweight and easy-to-cut properties. CNC machines allow designers and engineers to create detailed, accurate models and prototypes, whether for architecture, product development, or film production. - Art and Sculptures

Foam Cutter CNC machines are also used in the art world to create sculptures and large-scale installations. With the ability to cut foam into highly intricate designs, artists can bring their creative visions to life with precision and detail that would be difficult to achieve with traditional tools.

How Does a Foam Cutter CNC Work?

A Foam Cutter CNC machine operates by following a set of instructions encoded in CAD or CAM (Computer-Aided Manufacturing) software. These software programs allow users to design the shape they want to cut and input the specific dimensions and cutting paths into the machine. Once the design is ready, the CNC machine automatically performs the cutting based on these instructions.

There are different types of cutting tools that can be used with CNC machines, depending on the foam material and the desired result:

- Hot Wire Cutting

Hot wire cutting is one of the most common methods used in Foam Cutting CNC machines. The process involves using a thin wire that is heated to high temperatures, which then melts through the foam. This method is perfect for soft foams like polystyrene and polyurethane and results in a smooth, clean cut. - Rotary Blades

For denser or thicker foams, rotary blades are used. These blades rotate at high speeds, allowing the machine to cut through harder materials with ease. Rotary blades are ideal for creating clean cuts in thicker foams used in upholstery, insulation, or automotive parts. - Oscillating Blades

Oscillating blades are ideal for cutting through a variety of foam materials. The back-and-forth motion of the blade helps minimize drag, ensuring a smooth cut with minimal resistance.

The machine moves along pre-programmed cutting paths, following the design in the CAD file. With multi-axis CNC machines, operators can create 3D shapes or cut from different angles, enabling more complex projects.

Best Practices for Using Foam Cutter CNC Machines

To ensure that your Foam Cutter CNC machine operates at its best, here are some best practices to follow:

Regular Maintenance

Like any advanced machine, regular maintenance is essential for optimal performance. This includes cleaning the cutting tools, checking for wear and tear, and ensuring that the machine is calibrated properly. Routine checks on the mechanical and electrical components will prevent costly repairs and downtime.

Optimize Cutting Programs

Take full advantage of your CNC software by optimizing cutting programs for material efficiency. Using nesting software to arrange foam shapes efficiently on the foam sheet can reduce material waste and maximize productivity.

Operator Training

While CNC machines are automated, proper training is still necessary. Ensuring that your operators understand the software, machine settings, and safety protocols will lead to smoother operations and better results.

Safety Protocols

Since foam cutting involves sharp blades and hot wires, safety is crucial. Operators should wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection. Regular safety checks and clear signage around the CNC cutting area also help reduce the risk of accidents.

Conclusion

Foam Cutter CNC machines represent a leap forward in the precision and efficiency of foam cutting. From packaging to automotive manufacturing and artistic design, these machines offer unmatched versatility, speed, and accuracy, making them an invaluable tool in any production facility. By automating the cutting process, reducing material waste, and improving consistency, Foam Cutter CNC machines help businesses lower costs, improve quality, and increase production capacity.

Whether you’re looking to streamline your foam cutting operations or meet specific design requirements, investing in a Foam Cutter CNC machine is a smart decision that will elevate your business to the next level.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.