Blog

Custom CNC Stone Engraving

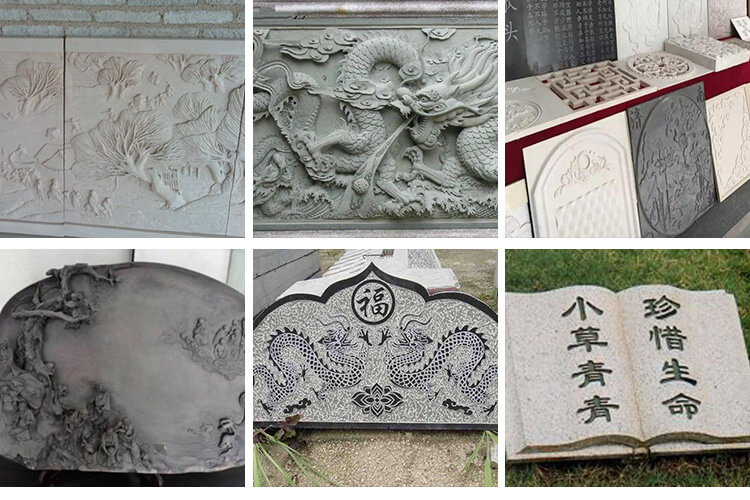

Stone engraving has long been associated with skill, craftsmanship, and tradition. However, the introduction of CNC stone engraving machines has dramatically shifted how artisans approach the craft, making the process more efficient, precise, and scalable. With these machines, stoneworkers can now achieve intricate details and complex designs that would have been unimaginable with traditional hand tools.

If you’ve ever wondered how the stone carving industry continues to evolve, CNC stone engraving is the answer. Let’s dive into how this cutting-edge technology works, its advantages, and how it’s revolutionizing custom stone projects.

The Technology Behind CNC Stone Engraving

CNC (Computer Numerical Control) stone engraving uses computer-driven machinery to carve, cut, and engrave detailed designs onto stone surfaces. Unlike traditional hand carving, which requires manual control and extensive experience, CNC machines follow pre-programmed instructions that ensure consistent results.The stone CNC machine refers to the CNC machine designed for processing various natural and artificial stone materials. For example, a stone CNC machine can process quartz stone, marble, slate, granite, ceramic tile, and many artificial stones.

At its core, CNC stone engraving begins with a digital design that’s created using specialized software. The design is then translated into a format that the CNC machine understands, usually in G-code, a programming language that instructs the machine’s movements. Once the stone is loaded onto the machine, the engraving begins. The precision of these machines is unmatched, and they can reproduce intricate designs with exact accuracy.

Why CNC Stone Carving is Gaining Popularity

In an industry traditionally dominated by hand tools, CNC stone engraving brings several benefits that make it a game-changer for stone carving. Below, we explore why more and more artisans, businesses, and homeowners are turning to this innovative technology.

1. Unmatched Precision and Detail

One of the key advantages of CNC stone engraving is the ability to achieve remarkable levels of detail. Hand-carved stonework, while beautiful, is limited by the artisan’s skill and the tools at their disposal. CNC machines, on the other hand, are capable of executing designs with a level of accuracy that is nearly impossible to replicate manually. Fine details, sharp lines, and intricate patterns can be carved into stone with extreme precision.

For example, intricate logos, portraits, or complex geometric patterns can be replicated multiple times with ease, ensuring that each piece is identical. This level of precision is ideal for applications like memorials, commercial signage, and decorative elements in architecture.

2. Speed and Efficiency

Traditional stone carving can be a slow and labor-intensive process, especially for large projects or when multiple pieces are needed. CNC stone carving machines drastically reduce the time required to complete these projects. What once took hours or even days can now be finished in a fraction of the time.

For businesses, this means the ability to take on more projects, fulfill orders faster, and keep production costs lower. For artisans, the ability to create detailed pieces in less time opens up more opportunities for creative exploration and expanding their portfolios.

3. Consistency and Reproducibility

When carving stone by hand, every piece is slightly different. While this adds a unique touch to each project, it can be problematic when precision and uniformity are needed. CNC stone router solves this issue by ensuring that every design is reproduced with the same exact level of detail and precision.

For businesses that require mass production or those working on large-scale projects, CNC technology ensures that each stone piece maintains the same quality as the last. This level of consistency is crucial in maintaining a high standard of work and meeting client expectations.

4. Increased Customization

CNC stone engraving provides the flexibility to create a wide range of custom designs. Whether you’re looking to engrave a detailed portrait, add a personal inscription, or create custom patterns for a stone feature, the machine can execute a variety of styles. Additionally, CNC machines can carve in 2D or 3D, giving you the ability to add depth and texture to your designs, something that’s difficult to achieve with traditional carving.

Whether you’re creating a one-of-a-kind memorial or a unique decorative feature, CNC stone engraving opens up endless possibilities for customization.

5. Reduced Labor Costs

While the initial investment in CNC machinery can be significant, the reduction in labor costs over time is substantial. CNC stone carving allows one operator to run multiple machines at once, reducing the need for a large team of skilled laborers. This efficiency translates to lower production costs, which can be a major advantage for small businesses and larger operations alike.

Applications of CNC Stone Engraving

The versatility of CNC stone engraving makes it ideal for a variety of industries and applications. Let’s take a look at some of the most common uses for this technology.

Memorial and Gravestone Engraving

One of the most popular uses of CNC stone engraving is for creating personalized memorials and gravestones. Families often want to inscribe names, dates, and personal messages on gravestones, and CNC technology allows for highly detailed, long-lasting engravings. Whether it’s a traditional gravestone or a more modern design, CNC machines can execute the perfect engraving every time.

Additionally, intricate artwork such as floral patterns, religious symbols, or even portraits can be created with precision and care, providing a meaningful tribute to loved ones.

Architectural Stonework

CNC engraving has also found its place in the world of architecture. From intricate stone facades to beautifully engraved countertops, architects and designers rely on CNC technology to create stunning stone elements. The ability to carve fine details into large stone pieces allows for more creativity and complexity in architectural design.

Whether it’s a decorative stone tile, an ornate fireplace, or a custom stone wall feature, CNC stone engraving ensures that architectural pieces are not only beautiful but also precise and durable.

Signage and Logos

Businesses often use CNC stone engraving to create high-end signage and logos. Stone signs are long-lasting and elegant, and with CNC technology, logos and text can be engraved into stone materials such as granite or marble. This type of engraving is especially popular in upscale businesses, memorial parks, and other high-traffic areas where durability is key.

The precision of CNC engraving ensures that logos remain sharp and legible over time, even in outdoor environments that may expose the sign to wear and tear.

Artistic Sculptures and Features

For artists and sculptors, CNC stone engraving opens up a world of new possibilities. Intricate sculptures and art pieces that once required immense time and effort can now be created with the help of CNC machines. The technology allows for intricate designs, creating everything from small statues to large-scale installations with fine detail and texture.

The Future of Stone Carving Machine

As technology continues to evolve, the potential for stone carving machine is limitless. Advances in machine capabilities, software, and design techniques are continually improving the precision and versatility of CNC stone carving. For those involved in the stone industry, whether in art, construction, or memorial work, these advancements offer exciting new opportunities for creativity and productivity.

In the future, we may see even more integration between CNC machines and 3D modeling software, allowing for seamless transitions from design to production. Additionally, as the cost of CNC technology continues to decrease, it is likely that more small businesses and independent artists will have access to these powerful tools, further democratizing the world of stone engraving.

Conclusion

CNC stone engraving has opened up new horizons for the stone industry, offering precision, efficiency, and customization that were once unimaginable. Whether you’re creating a personalized memorial, architectural stonework, or a stunning sculpture, CNC technology provides the tools necessary to bring your designs to life with accuracy and speed. The combination of artistry and technology is transforming the world of stonework, and the possibilities are endless for anyone looking to explore the art of stone engraving in a modern, innovative way.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.