Blog

5 axis stone cnc machine for Granite & Marble

In the world of stone processing, precision, versatility, and efficiency are the key factors that determine the quality of finished products. Whether you’re working with granite, marble, or other natural stones, achieving intricate and high-quality designs has always been a challenge. Traditional stone-cutting methods, although reliable, often fall short when it comes to intricate designs, 3D carvings, and high precision. This is where 5-axis stone CNC machines come in. These machines have revolutionized stone processing by offering greater flexibility, speed, and precision. If you’re in the stone industry, investing in a 5-axis CNC machine could be a game-changer for your business.

Next, we will explore the benefits, functions, and capabilities of the 5-axis stone CNC machine for working with granite and marble, and how it can elevate your stone processing operations.

What is a 5 Axis Stone CNC Machine?

5-axis CNC (Computer Numerical Control) machine is an advanced piece of equipment that operates on five different axes: three linear (X, Y, Z) and two rotational (A, B). This unique capability allows the tool to move in multiple directions simultaneously, which is essential for precise cutting, milling, and shaping of materials like granite and marble. Unlike traditional 3-axis machines, which only move in straight lines (up/down, left/right, forward/backward), a 5-axis machine can rotate and tilt, enabling it to cut complex shapes and contours with incredible accuracy.

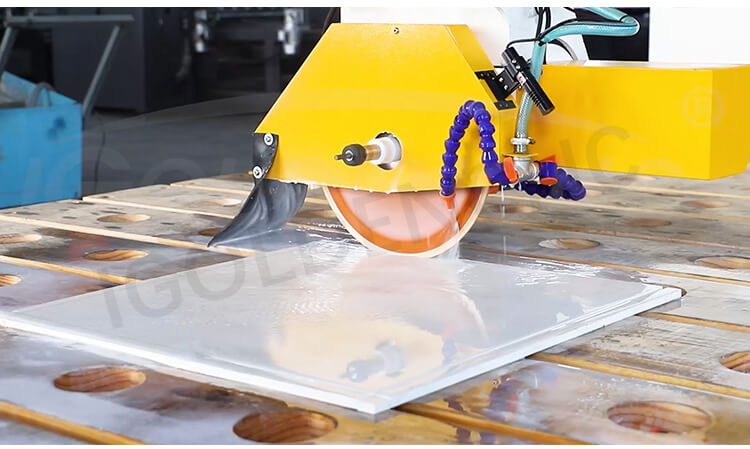

5 axis stone cnc machine for Granite & Marble Most refer to the Stone Bridge saw is a specialized machine used primarily in the stone fabrication industry. It is designed to cut large stone slabs into precise shapes and sizes. The machine consists of a sturdy bridge structure, a diamond blade, and a motorized system that moves the blade across the stone surface.Stone cnc machine machine is a type of stone cutting machine designed for diversified stone business. And CNC stone bridge cutters are cutting machines made for cutting natural stone, granite, marble, and ceramics.

With a CNC stone saw, it is good at special-shaped cutting, polishing, edging, drilling, and chamfering of granite, marble, quartz, artificial stone, and natural stone. Therefore, it is also known as stone bridge saw cutting machine, stone bridge saw for quartz, bridge saw for granite, tile bridge saw, marble bridge cutting machine, stone bridge saw cutter, etc.

Key Features of the 5-Axis Stone CNC Machine

Multidimensional Movement

The most significant advantage of a 5-axis CNC machine is its multidimensional movement. The machine can operate across five axes. Thus, it can reach complex angles and curves impossible for a 3-axis machine. This movement capability offers unmatched flexibility, making it perfect for high-precision tasks like intricate carving, milling, and complex cutting profiles.

Precision Cutting and Shaping

Granite and marble are some of the hardest and most challenging materials to work with in the stone industry. Traditional methods can result in imprecise cuts and longer processing times. With a 5-axis CNC machine, you can achieve highly detailed, precise cuts with minimal effort. The toolpath is guided by digital instructions, ensuring that every cut and shape is executed to the exact specifications. This results in fewer errors, less material waste, and a much faster turnaround time for your projects.

Advanced Software Integration

5-axis stone CNC machines are integrated with powerful CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This allows operators to design complex stone carvings and modifications in a 3D digital environment before any physical work begins. These designs are then sent to the machine, which translates them into precise cuts, engravings, or sculptures. This integration streamlines the design-to-production process and enables the creation of highly complex stonework that would be time-consuming or impossible to achieve manually.

Increased Productivity

The advanced features of the 5-axis stone CNC machine lead to higher productivity levels. These machines can work continuously without the need for manual intervention, allowing operators to focus on other aspects of the project. Additionally, since these machines are highly efficient, they significantly reduce the time required to complete intricate projects, leading to faster delivery and more satisfied clients.

Minimal Human Error

The automation provided by CNC technology minimizes human error. As the machine follows a digital path based on precise software instructions, the chance for mistakes or inconsistencies is drastically reduced. This is especially crucial when working with high-value materials like granite and marble, where small errors can be costly in terms of both time and money.

Why Choose a 5-Axis CNC Stone Cutting Bridge Saw for Granite & Marble?

Granite and marble are popular materials for a wide range of applications, from kitchen countertops to all kinds of tables. However, both materials present challenges due to their hardness, weight, and density. Working with these stones requires specialized tools, and a 5-axis CNC machine offers several key benefits for those working with granite and marble:

5-Axis CNC Machines for various Angle cutting

5-axis CNC machines are essential for achieving complex cuts and angles that are crucial in stone projects like countertops, monuments, and intricate architectural designs. These machines offer the ability to cut curves, chamfers, and detailed angles with precision, providing results that would be nearly impossible with manual tools.

Moreover, 5-axis CNC machines are highly effective in ensuring efficient material usage. By providing exact cuts, these machines reduce waste, especially when working with expensive stones like granite and marble. This precision helps businesses minimize costs, particularly in industries like monument making, where waste reduction is critical. Whether you’re creating custom pieces or handling high-volume production, the machine’s versatility in both custom and high-volume production makes it a great choice. The automation allows for smooth transitions between different designs and projects, ensuring efficient production without compromising quality.

Consistency and Quality in Stone Projects

One of the most valuable benefits of a 5-axis CNC machine is its ability to deliver consistent quality across projects. Whether working on a custom piece or producing multiple identical units, CNC technology ensures precise cuts every time. This consistency is crucial for fabricating stone elements like countertops or monuments. Uniformity is key to meeting both customer expectations and industry standards. The 5-axis CNC machine maintains high precision across various designs and materials. It is a reliable, cost-effective solution for both small-scale and large-scale stone production.

Bridge Saw Advantage

- Using automatic touch human-machine interface, intuitive operation, simple and convenient;

- Main core control component USES the first-line brand, stable performance and long life;

- Can spin 0 ° to 360 ° and 90 ° inclined processing, used in any direction and any Angle of the cutting;

- Implementation heterosexual complex surface machining, cutting, milling, drilling and multi-function in one;

- Increase other optional features, such as photo function layout, automatic measuring plate thickness, automatic pressure material, etc.

Applications of 5-Axis CNC Machines for Granite and Marble

The versatility of 5-axis CNC machines makes them suitable for a wide range of applications in both commercial and artistic stonework. Here are some common uses for these machines in the granite and marble industries:

- Custom Countertops: The demand for custom granite and marble countertops continues to rise. A 5-axis CNC machine can produce these countertops with high precision. It can cut intricate edge profiles, create sink cutouts, and even engrave custom designs or logos on the surface.

- Architectural Stonework: Architects and builders often require custom-cut stone panels, columns, and decorative elements. A 5-axis CNC machine is ideal for producing these complex shapes. It ensures a high level of accuracy and attention to detail, making it a valuable tool for architectural projects.

- Vanity tops: It is also used in the fabrication of bathroom vanity tops, ensuring accurate cutouts for sinks and faucets.

Conclusion: The Future of Stone Processing with 5-Axis CNC Machines

The 5-axis stone CNC machine is a game-changer for industries that rely on stonework, offering unparalleled precision, versatility, and speed. Whether you’re working with granite, marble, or other types of natural stone, these machines provide the accuracy required for custom designs, 3D carvings, and complex cuts. The ability to streamline production processes and reduce human error makes these machines an essential tool for stone fabricators, and artists alike.

As the demand for custom stone products continues to grow, investing in a 5-axis CNC machine is a smart move for businesses looking to stay competitive and deliver high-quality products to their customers. From countertop fabrication to stone art, the possibilities are endless with the power of 5-axis CNC technology.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.