Blog

5 Axis CNC Stone Cutting Machine for Marble and Granite

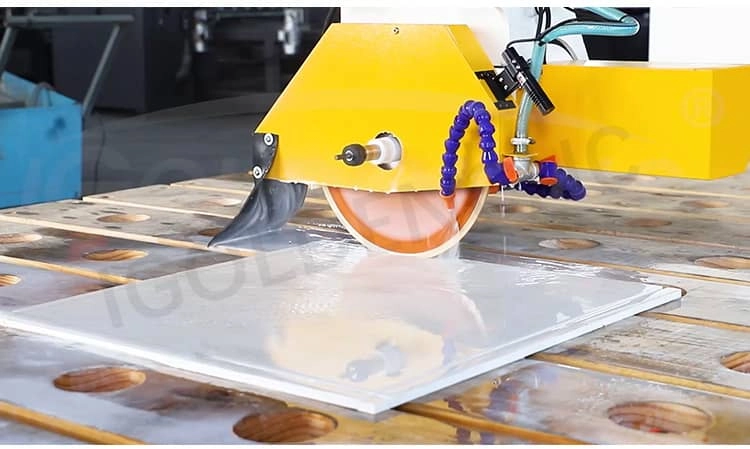

In the world of stone processing, precision, speed, and versatility are essential. Whether crafting marble sculptures or cutting granite slabs for countertops, the 5-axis CNC stone cutting machine has transformed the industry. With outstanding capabilities, it’s the top choice for pros seeking efficient, flawless results. Let’s explore the characteristics, advantages, applications and purchase considerations of marble and granite.

What is a 5 Axis CNC Stone Cutting Machine?

5 axis CNC (Computer Numerical Control) stone cutting machine is an advanced piece of machinery designed to cut, carve, and shape stones such as marble, granite, and other natural materials with remarkable precision. Unlike traditional 3-axis machines, the 5-axis CNC stone cutting machine has two additional rotational axes that allow it to work from multiple angles, enabling complex cuts and intricate designs that would otherwise be impossible with conventional machinery.

The machine operates through computer programming, allowing operators to input precise measurements, shapes, and cutting paths. 5 axis stone cutting machine is advanced equipment for cutting and shaping stone materials. Unlike traditional machines, which usually operate on two or three axes, a 5-axis machine moves in five directions. This allows for more complex and precise cuts, perfect for detailed work and intricate designs.

How Does CNC Stone Center Work?

A 5-axis CNC stone stone center works by combining linear and rotary movements to precisely control the cutting tool’s position. Here’s a breakdown of the machine’s operation:

- Linear Motion: The machine’s three linear axes (X, Y, and Z) control the basic horizontal and vertical movement of the cutting tool. These axes allow for basic cutting in two dimensions.

- Rotational Axes (A and B): The additional two axes rotate the cutting tool or the workpiece, allowing for more intricate cuts. The A-axis controls rotation around the X-axis, while the B-axis controls rotation around the Y-axis. These rotational movements give the machine the ability to cut from multiple angles, making it ideal for producing complex shapes and detailed designs.

- Computer Control: The machine is controlled by a computer, which directs the tool’s movements based on pre-programmed instructions. The cutting paths are meticulously calculated and fed into the CNC system, ensuring precision in every cut.

- Tool Movement and Cutting: As the CNC machine moves the tool along the pre-programmed paths, it cuts through the stone with the utmost precision, following the exact specifications set by the operator. The high-speed spindles and diamond-tipped tools help achieve smooth and accurate results, even with tough materials like granite.

Benefits of Using a Stone CNC Router

There are several advantages to using a 5 axis CNC stone cutting machine, particularly when working with materials like marble and granite:

1. Precision and Accuracy

One of the most significant advantages of a 5 axis CNC stone router is its ability to provide unmatched precision and accuracy. With five independent axes of movement, the machine can execute complex cuts, intricate details, and precise carvings with ease. This level of accuracy is crucial for industries such as stone sculpture, architecture, and countertop production, where even a slight mistake can result in a loss of materials or functionality.

2. Versatility

The 5 axis CNC stone cutting machine is incredibly versatile, allowing for a wide range of operations. From simple cuts to intricate 3D designs, the machine can handle a variety of stone processing tasks, including engraving, polishing, beveling, and carving. Its ability to rotate the cutting tool and workpiece simultaneously allows for the creation of complex shapes, angles, and surfaces that are difficult or impossible to achieve with traditional methods.

3. Increased Productivity

Thanks to its speed and precision, the 5 axis CNC stone cutting machine dramatically increases productivity. It can operate continuously without the need for manual intervention, reducing the amount of labor required and increasing throughput. This is particularly beneficial in industries where high-volume production is necessary, such as in the manufacture of countertops, tiles, and decorative stone elements.

4. Reduced Material Waste

With traditional cutting methods, the risk of human error is high, which can lead to wasted materials and costly mistakes. A 5 axis CNC stone cutting machine reduces this risk by following pre-programmed cutting paths with precision, ensuring that materials are used efficiently. This results in less waste and better cost-effectiveness over time.

5. Improved Safety

Using a 5-axis CNC stone cutting machine improves safety for operators compared to manual methods. Since the machine is controlled by a computer, operators are less likely to come into contact with moving parts or cutting tools. Additionally, many modern CNC machines are equipped with safety features like automatic shutdowns, tool collision protection, and enclosed workspaces, further reducing the risk of injury.

Applications of 5 Axis CNC Stone Cutting Bridge Saw

The versatility and precision of 5-axis CNC stone cutting bridge saw make them invaluable in several industries. Below are some of the key applications:

1. Marble and Granite Countertops

In the kitchen and bathroom industry, 5 axis CNC machines are essential for manufacturing high-quality granite and marble countertops. These machines can create intricate edges, smooth finishes, and precise cutouts for sinks and faucets. With their ability to handle complex designs and contours, they ensure that countertops are both functional and aesthetically pleasing.

2. Stone Sculpting and Artworks

For artists using stones, the 5-axis CNC machine brings designs to life. From classical to modern art, it offers precision for carving patterns, figures, and textures.

3. Architectural Stonework

Architectural firms use 5-axis CNC stone cutting machines to create detailed stone elements for buildings, monuments, and landscaping projects. Whether it’s intricate columns, stone facades, or decorative stone panels, the machine allows for high-level customization and precision that meets architectural specifications.

4. Stone Restoration

Restoring old stone structures or monuments requires the ability to replicate original patterns and designs with high accuracy. The 5 axis CNC machine makes this process easier by allowing restorers to replicate stone carvings and details exactly, ensuring that the original appearance is preserved.

5. Case Study: A Landmark Building

A notable example is using 5-axis stone cutting machines in constructing a landmark building. The architects needed precise and complex stonework achievable only with a 5-axis machine. Consequently, the result was a stunning façade that became a defining feature of the building.

Choosing the Right 5-Axis CNC Stone Cutting Machine

When purchasing a 5 axis CNC stone cutting router, there are several factors to consider to ensure that you select the right one for your needs:

1. Size and Capacity

The size and cutting capacity of the machine will depend on the type and scale of your projects. Larger machines with bigger workspaces are ideal for cutting large slabs of marble or granite, while smaller models are better suited for more detailed or intricate work.

2. Software and Control System

The software used to program the machine is crucial for ensuring precise and efficient operations. Look for a machine that supports user-friendly software with advanced features such as 3D modeling, automatic toolpath generation, and customizable settings.

3. Power and Speed

Consider the power and speed of the machine’s motor, which directly affects cutting efficiency. Higher-powered motors allow for faster cutting, but the speed should also be balanced with precision to avoid compromising the quality of the cut.

4. Reliability and Durability

Since you subject stone cutting machines to heavy use, you must choose a machine built with high-quality components that can withstand the demands of the industry. Durability and reliability are key factors in reducing downtime and maintenance costs.

5. Support and Service

Finally, ensure that the manufacturer provides adequate support and service. Look for a company with good customer support, having available technicians and spare parts when needed.

Conclusion

The 5-axis CNC stone cutting machine is an invaluable tool for anyone working with marble, granite, or other stones. Offering unmatched precision, versatility, and productivity, this advanced machine can handle everything from simple cuts to intricate carvings, making it essential for industries ranging from construction and architecture to art and sculpture.

Whether you’re creating beautiful countertops, intricate sculptures, or detailed architectural elements, a 5 axis CNC stone cutting machine will help you achieve flawless results every time. When purchasing a machine, be sure to consider factors such as size, power, software, and reliability to ensure that it meets your specific needs.

By investing in this powerful technology, you can unlock new possibilities in stone processing and elevate your craftsmanship to the next level.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.