Blog

5-Axis CNC Router: Precision Cutting for Complex Projects

5-axis CNC router is at the forefront of advanced manufacturing, offering unparalleled precision and versatility. These machines are designed to handle complex tasks across various industries, from aerospace to stone fabrication. By enabling the tool or workpiece to move along five different axes simultaneously, these routers make it possible to create intricate shapes and surfaces that were once deemed impossible.

In this blog, we’ll dive into the key features, benefits, applications, and considerations when choosing a 5-axis CNC router to maximize your production efficiency and quality.

What Is a 5-Axis CNC Router?

The 5-axis CNC router called 5 axis cnc machining is a computer-controlled cutting machine that operates along five different axes: X, Y, Z (linear movements), and A and B (rotational movements). Unlike 3-axis or 4-axis routers, the additional rotational axes provide enhanced flexibility, allowing the tool to approach the material from multiple angles without repositioning the workpiece manually.

This capability is particularly beneficial for creating intricate 3D designs, undercuts, and complex geometries, making the 5-axis CNC machine a staple in industries requiring high precision.

Key Features of 5-Axis CNC Routers

1.Simultaneous Multi-Axis Movement

The ability to move along five axes simultaneously ensures efficient and seamless production of complex shapes, reducing machining time.

2.High-Speed Spindles

Equipped with high-RPM spindles, 5-axis routers can handle a wide variety of materials, from metals and plastics to stone and wood.

3.Large Working Area

Many 5-axis CNC routers offer expansive working zones to accommodate large-scale projects, such as aerospace components or stone slabs.

4.Advanced Control Systems

The integration of sophisticated software like CAD/CAM enables precise toolpath generation, ensuring consistent results across batches.

5.Tool-Length Compensation

Automatic tool-length adjustment ensures precision in material removal, even when switching between tools of different sizes.

6.Sturdy Construction

Built for demanding applications, these machines feature rigid frames and durable components that minimize vibration for smooth finishes.

Benefits of 5-axis machine

- Enhanced Precision:The ability to approach the workpiece from multiple angles eliminates errors caused by manual repositioning, ensuring flawless results.

- Increased Efficiency:Simultaneous multi-axis cutting reduces production time and allows for complex tasks to be completed in a single setup.

- Versatility:Suitable for diverse materials such as wood, aluminum, granite, and marble, these routers can be used across industries like construction, automotive, and design.

- Cost Savings:While the initial investment may be high, 5-axis CNC routers reduce material wastage and labor costs, providing long-term financial benefits.

- Improved Surface Finish:The additional axes allow for smooth and continuous cuts, resulting in superior surface quality with minimal post-processing.

Applications of 5 axis cnc router manufacturers

1.Stone Fabrication

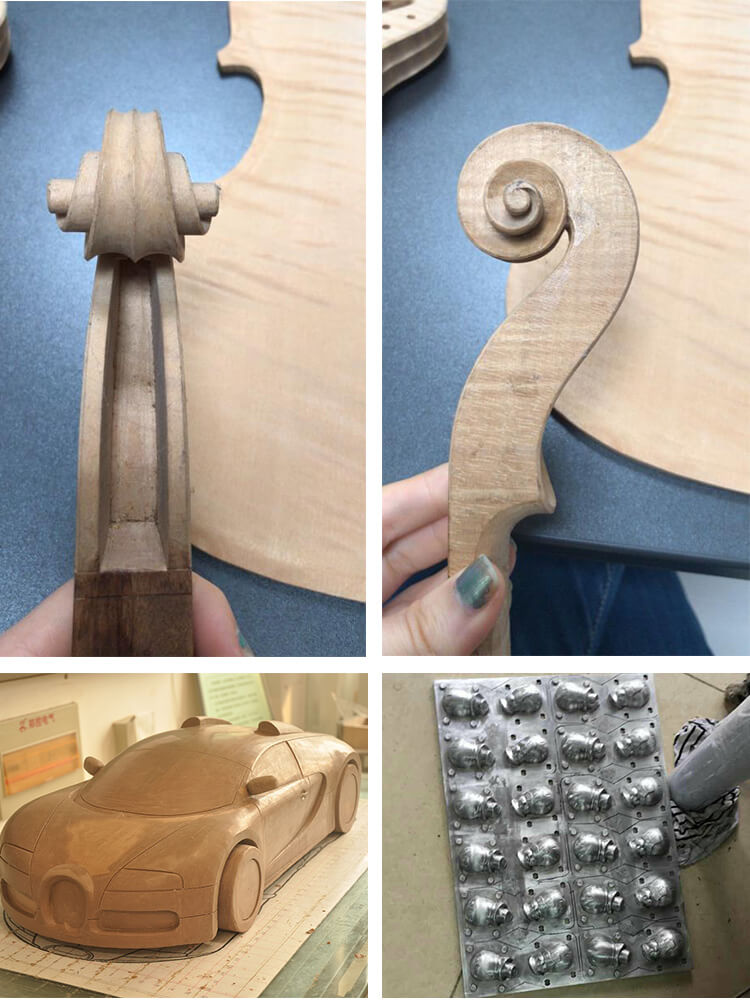

Sculptures and Statues: Crafting intricate 3D designs for decorative and artistic purposes.

Countertops and Sinks: Precision cutting and engraving of stone surfaces for custom kitchen and bathroom applications.

2.Aerospace Components

Producing complex parts like turbine blades and structural components with tight tolerances.

3.Automotive Industry

Crafting molds, prototypes, and lightweight composite parts for vehicles.

4.Woodworking

Creating furniture, ornate carvings, and curved panels with exceptional detail.

5.Metalworking

Machining parts for tools, medical devices, and industrial machinery.

6.Marine Applications

Producing hulls, propellers, and other components for boats and ships.

Factors to Consider When Choosing 5 axis cnc machining Center

- Material Compatibility:Determine whether the router is optimized for the materials you work with, such as metals, stone, or wood.

- Spindle Power:Choose a router with sufficient spindle power to cut through dense materials like granite or metals.

- Software Support:Ensure the machine supports advanced CAD/CAM software for seamless design and production.

- Machine Size and Workspace:Select a machine with a worktable large enough to handle your project sizes.

- Cost and ROI:Consider the long-term benefits, including increased productivity and reduced errors, when evaluating the machine’s price.

- Ease of Maintenance:Opt for a machine with easily replaceable components and accessible support services.

Maintenance Tips for Optimal Performance

- Regular Cleaning:Remove debris and dust after each use to prevent clogging and ensure smooth operation.

- Tool Inspection:Regularly check and replace cutting tools to maintain precision and avoid damage to the machine.

- Lubrication:Keep all moving parts properly lubricated to reduce wear and extend the machine’s lifespan.

- Software Updates:Keep the control software updated to ensure compatibility with the latest design tools and improved performance.

- Calibration Checks:Periodically calibrate the machine to maintain accuracy, especially after heavy usage or long idle periods.

Why Invest in 5-Axis CNC Routers?

A 5-axis CNC router is more than just a machine—it’s a gateway to innovation. Its ability to handle complex projects with precision and efficiency makes it a valuable asset for businesses aiming to elevate their production capabilities. Whether you’re crafting intricate sculptures, machining high-tech components, or creating custom stonework, a 5-axis CNC router ensures top-tier results every time.

5-axis CNC routers redefine precision and efficiency in modern manufacturing. By automating intricate processes and enabling seamless multi-axis cutting, these machines cater to diverse industries and applications. Investing in a 5-axis CNC router not only enhances your capabilities but also provides a competitive edge in today’s market.

Unlock the potential of your business with a 5-axis CNC router and experience the future of precision cutting and engraving.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.